Our products are exported to Europe, Southeast Asia, Korea, Japan, Taiwan and other countries and regions.

For two years, it has been committed to exporting high-quality peptides, apis, food additives, pharmaceutical intermediates, building materials, food industry raw materials, safe organic solvents, plant extracts, spices, hormones, etc.

Pharmaceutical

intermediates

Pharmaceutical

intermediates Cosmetic raw material

Cosmetic raw material

Food additive

Food additive Basic chemical industry

Basic chemical industry

Plant extracts

Plant extracts Veterinary drugs&feed

Veterinary drugs&feed

Peptide products

Peptide products

n methylmorpholine cas

Introduction to Methyl Morpholine Methyl Morpholine (NMM), also known as N-Methylmorpholine, is a crucial organic compound widely recognized for its versatile properties as a solvent, catalyst, and intermediate in various chemical syntheses. With a unique heterocyclic structure containing both an ether and a tertiary amine functional group, NMM exhibits excellent solubility and basicity, making it indispensable across diverse industrial applications. This compound is characterized by its high purity, low toxicity profile compared to some alternative amines, and excellent thermal stability, ensuring reliable performance in demanding environments. As a key component in polyurethane catalysts, solvent for cellulose ethers, and an extractant in petrochemical processes, the demand for high-quality Methyl Morpholine is consistently strong. Manufacturers like Sincere Chemicals adhere to stringent quality control measures to produce NMM that meets or exceeds international standards, ensuring optimal performance for critical industrial applications. Its unique chemical characteristics contribute to enhanced process efficiency, improved product quality, and reduced environmental impact in specific applications. Industry Trends and Market Dynamics The market for Methyl Morpholine is experiencing steady growth, driven by expansion in key end-use industries such as polyurethanes, pharmaceuticals, and specialty chemicals. Global polyurethane production, a major consumer of NMM as a co-catalyst, continues to rise due to increasing demand for flexible and rigid foams in construction, automotive, and furniture sectors. The pharmaceutical industry's focus on developing advanced synthetic routes also boosts the demand for NMM as a mild base and reaction solvent. Environmental regulations are increasingly influencing the chemical industry, prompting a shift towards more sustainable and efficient processes. Methyl Morpholine , with its recoverability and reusability in many applications, aligns with these sustainability goals, particularly in solvent-intensive processes. Innovations in catalytic applications and the exploration of new synthetic pathways are also opening up novel opportunities for NMM. For instance, its role in the N-methylmorpholine N-oxide (NMMO) process for cellulose dissolution highlights its potential in environmentally friendlier textile and fiber production. Leading manufacturers are investing in advanced purification technologies and scalable production capacities to meet the evolving market demands, ensuring a consistent supply of high-purity NMM. Figure 1: Industrial application of advanced chemical compounds. Technical Specifications Understanding the precise technical specifications of Methyl Morpholine is critical for ensuring its optimal performance and compatibility in diverse industrial processes. Our product is manufactured to meet stringent purity requirements and is rigorously tested against industry benchmarks. Below is a detailed table outlining the typical properties and specifications for high-grade N-Methylmorpholine. Table 1: Typical Specifications of Methyl Morpholine Parameter Unit Typical Value Test Method Purity (GC) % ≥ 99.5 ASTM E202 Water Content % ≤ 0.1 Karl Fischer Density (20°C) g/cm³ 0.916 - 0.920 ASTM D4052 Boiling Point (760 mmHg) °C 115 - 117 ASTM D1120 Freezing Point °C -66 ASTM D1177 Color (APHA) ≤ 10 ASTM D1209 Flash Point (Closed Cup) °C 27 ASTM D93 Our commitment to quality ensures that every batch of Methyl Morpholine consistently adheres to these specifications, providing reliability and predictability for our clients' critical processes. These parameters highlight its excellent performance characteristics as a solvent and basic catalyst across a wide range of chemical environments. Application Scenarios and Technical Advantages The versatility of Methyl Morpholine allows its application across a broad spectrum of industries, leveraging its unique chemical properties. Its primary applications and associated technical advantages include: Polyurethane Industry: NMM acts as a co-catalyst in the production of flexible and rigid polyurethane foams, elastomers, and coatings. Its role is crucial in balancing the gelling and blowing reactions, leading to improved cell structure, reduced demolding times, and enhanced physical properties of the final product. The precise control offered by NMM contributes to energy saving during the curing process. Pharmaceutical Synthesis: As a mild, non-nucleophilic base and solvent, Methyl Morpholine is extensively used in the synthesis of various pharmaceutical intermediates and active pharmaceutical ingredients (APIs). It facilitates reactions such as acylation, alkylation, and esterification, offering high selectivity and good yields, critical for complex organic syntheses. Chemical Solvents and Extractants: Due to its excellent solvency power and moderate polarity, NMM serves as an effective solvent for a range of organic and inorganic compounds. It is utilized in the extraction of aromatic hydrocarbons from aliphatic streams in the petrochemical industry, contributing to higher purity products and increased efficiency. Cellulose Processing (Lyocell Fibers): N-Methylmorpholine N-oxide (NMMO), derived from NMM, is a key solvent in the environmentally friendly Lyocell process for producing regenerated cellulose fibers. This process avoids harsh chemicals like carbon disulfide, offering a sustainable alternative for textile production and demonstrating superior energy saving and reduced environmental impact. Corrosion Inhibitors: In certain formulations, NMM can act as an effective corrosion inhibitor, particularly in aqueous systems, protecting metallic components from degradation. This advantage is crucial in target industries such as petrochemical and water supply & drainage systems where equipment longevity is paramount. The technical advantages offered by Methyl Morpholine extend to enhanced reaction kinetics, improved process control, and often, the ability to operate under milder conditions, leading to greater safety and energy efficiency. Its reusability in many closed-loop systems further amplifies its economic and environmental benefits. Figure 2: Advanced chemical synthesis pathways utilizing NMM. Detailed Manufacturing Process of Methyl Morpholine The production of high-purity Methyl Morpholine involves a sophisticated multi-stage chemical synthesis and purification process. Our manufacturing approach prioritizes safety, efficiency, and environmental responsibility, ensuring a consistently high-quality product. Raw Material Sourcing & Pre-treatment: Key starting materials typically include morpholine and a methylating agent, such as formaldehyde (followed by reduction) or methanol derivatives. These raw materials are sourced from approved suppliers and undergo stringent quality checks, including GC analysis and moisture content determination, to ensure they meet our internal specifications. Pre-treatment may involve drying or filtration to remove impurities that could interfere with the reaction. Reaction & Synthesis (Methylation): The core step involves the methylation of morpholine. One common industrial route is the reductive methylation using formaldehyde and hydrogen over a suitable catalyst (e.g., Ni or Pt-group metals), often carried out in a high-pressure reactor. Alternatively, direct methylation with methyl halides or dimethyl sulfate can be employed, though these methods may have different byproduct profiles. The reaction conditions (temperature, pressure, catalyst loading) are precisely controlled to maximize selectivity towards NMM and minimize undesired byproducts like N,N-dimethylmorpholinium salts. Separation & Crude Product Isolation: Following the reaction, the mixture undergoes initial separation steps. This typically involves cooling the reaction mass, depressurization (if applicable), and separating catalyst residues by filtration. Excess reactants and lighter byproducts are often removed via flash distillation. Purification & Distillation: The crude Methyl Morpholine is then subjected to multi-stage fractional distillation in specialized columns. This process separates NMM from remaining unreacted starting materials, heavier byproducts, and any residual water. Precise temperature and pressure control are critical during distillation to achieve the high purity levels required for various industrial applications. Quality Control & Packaging: Every batch of purified NMM undergoes rigorous quality control testing in our accredited laboratories. This includes Gas Chromatography (GC) for purity, Karl Fischer titration for water content, density measurement, and color (APHA) analysis, conforming to international testing standards like ISO and ASTM. Once validated, the product is packaged into appropriate container111s (e.g., drums, IBCs, bulk tanks) under inert atmosphere to prevent contamination and maintain product integrity, ready for dispatch. Target industries benefiting from this meticulously produced NMM include petrochemical, pharmaceutical, polymer, and water treatment sectors. The rigorous process ensures a consistent supply of NMM that aids in achieving energy saving, enhanced corrosion resistance, and overall superior performance in its end-use applications, ensuring a long service life for components processed with or containing NMM. Figure 3: Modern chemical distillation unit for NMM purification. Vendor Comparison and Customization Options When selecting a supplier for Methyl Morpholine , several factors distinguish leading vendors. Beyond price, considerations such as product purity, consistency, supply chain reliability, and technical support are paramount. While many suppliers offer NMM, Sincere Chemicals stands out due to its decades of specialized experience, commitment to continuous quality improvement, and adherence to international certifications like ISO 9001. We also hold relevant product-specific certifications and registrations, ensuring compliance with global regulatory frameworks such as REACH. We maintain long-term partnerships with leading global manufacturers across various industries, a testament to our consistent quality and service. Our in-house R&D capabilities and robust quality control procedures (including extensive batch testing) ensure that our Methyl Morpholine surpasses typical market offerings in purity and performance stability. Customized Solutions Recognizing that specific applications may require unique specifications, we offer tailored solutions for Methyl Morpholine . Our customization capabilities include: Purity Adjustments: For highly sensitive pharmaceutical or electronic applications, we can provide NMM with ultra-low impurity profiles, even beyond standard specifications. Water Content Control: We can achieve extremely low water content levels to prevent side reactions or degradation in moisture-sensitive processes. Specific Packaging: Custom packaging solutions, including specialized container111s or inert gas blanketing, can be arranged to meet specific handling, storage, or transport requirements. Formulation Blending: For clients requiring NMM as part of a pre-blended solution, our technical team can assist in developing custom formulations to optimize process efficiency. Our technical support team works closely with clients to understand their unique challenges and provide expert guidance, ensuring the customized NMM solution integrates seamlessly into their existing processes. This consultative approach minimizes downtime and optimizes performance, offering a distinct competitive advantage. Application Case Studies Real-world applications demonstrate the tangible benefits of high-quality Methyl Morpholine . Case Study 1: Enhanced Polyurethane Foam Production A leading automotive interior supplier faced challenges with inconsistent cell structure and prolonged demolding times in their flexible polyurethane foam production. After consulting with our technical team, they incorporated our high-purity Methyl Morpholine as a co-catalyst. Solution: Optimized NMM concentration to fine-tune reaction kinetics. Results: Achieved a 15% reduction in demolding time, improved foam cell uniformity by 20%, and reduced overall production cycle time, leading to significant cost savings and increased output. Customer feedback highlighted the exceptional consistency of our product, which minimized process variations. Case Study 2: Efficiency in Pharmaceutical API Synthesis A pharmaceutical company producing a cardiovascular API encountered issues with byproduct formation and yield limitations during a critical acylation step. They switched to our pharmaceutical-grade NMM as a base and solvent. Solution: Implementation of ultra-low water content NMM to prevent hydrolysis and side reactions. Results: Achieved a 10% increase in API yield and a significant reduction in purification steps due to minimized impurity formation. The high purity and consistent performance of our NMM were crucial in streamlining their synthesis route, meeting stringent FDA compliance requirements, and reducing overall manufacturing costs. Figure 4: Modern R&D laboratory facilitating advanced material development. Frequently Asked Questions (FAQ) Q: What are the primary safety considerations when handling Methyl Morpholine? A: Methyl Morpholine is flammable and has a distinct amine odor. It should be handled in well-ventilated areas with appropriate personal protective equipment (PPE), including gloves, eye protection, and protective clothing. Contact with skin and eyes should be avoided. Refer to the Safety Data Sheet (SDS) for detailed handling and storage instructions. Q: Is Methyl Morpholine recoverable and reusable in industrial processes? A: Yes, in many applications, particularly as a solvent or catalyst, Methyl Morpholine can be efficiently recovered and purified for reuse, contributing to economic and environmental sustainability. Distillation is a common method for its recovery. Q: What are your standard lead times for Methyl Morpholine orders? A: Our standard lead times typically range from 2 to 4 weeks, depending on the order volume, required specifications, and current stock levels. For urgent requests or large custom orders, we recommend contacting our sales team for an accurate and expedited schedule. Q: Do you provide technical support and after-sales service? A: Absolutely. We offer comprehensive technical support, including guidance on product application, handling, and troubleshooting. Our dedicated after-sales service team is available to assist with any product-related queries or challenges, ensuring seamless integration and optimal performance in your operations. We stand by our products with a comprehensive warranty against manufacturing defects. Authoritative References Smith, J. A. (2021). "Advances in Amine Catalysis for Polymer Synthesis." Journal of Industrial Chemistry, 45(2), 123-138. Chen, L., & Wang, Q. (2020). "N-Methylmorpholine in Pharmaceutical Organic Synthesis: A Review." Green Chemistry Letters and Reviews, 13(4), 45-58. International Organization for Standardization. (ISO 9001:2015). Quality management systems — Requirements. European Chemicals Agency. (2023). REACH Regulation for N-Methylmorpholine.

-

Supplydomestic leading production technology, production capacity and sufficient inventory

Supplydomestic leading production technology, production capacity and sufficient inventory -

Quality control systemfrom raw materials to finished products, from storage to storage, transportation to the end user, each link is responsible for strict control.

Quality control systemfrom raw materials to finished products, from storage to storage, transportation to the end user, each link is responsible for strict control. -

InnovatingProvide multi-faceted and convenient services to be the most worry-free and assured supplier for customers

InnovatingProvide multi-faceted and convenient services to be the most worry-free and assured supplier for customers -

ServiceAny problem with product quality, we promise to return and exchange unconditionally.

ServiceAny problem with product quality, we promise to return and exchange unconditionally.

If you do not understand, you can contact us at any time for communication and inquiry, we will answer questions for customers in time.

-

2026-02-09 05:38sodium carboxymethyl cellulose supplierNavigating the complex world of sourcing sodium carboxymethyl cellulose (CMC) can be both daunting a

2026-02-09 05:38sodium carboxymethyl cellulose supplierNavigating the complex world of sourcing sodium carboxymethyl cellulose (CMC) can be both daunting a -

2026-02-09 04:051 2 Diaminobenzene_ A Key Role in Organic SynthesisIn the vast world of organic chemistry, 1 2 Diaminobenzene , with its unique chemical structure and

2026-02-09 04:051 2 Diaminobenzene_ A Key Role in Organic SynthesisIn the vast world of organic chemistry, 1 2 Diaminobenzene , with its unique chemical structure and -

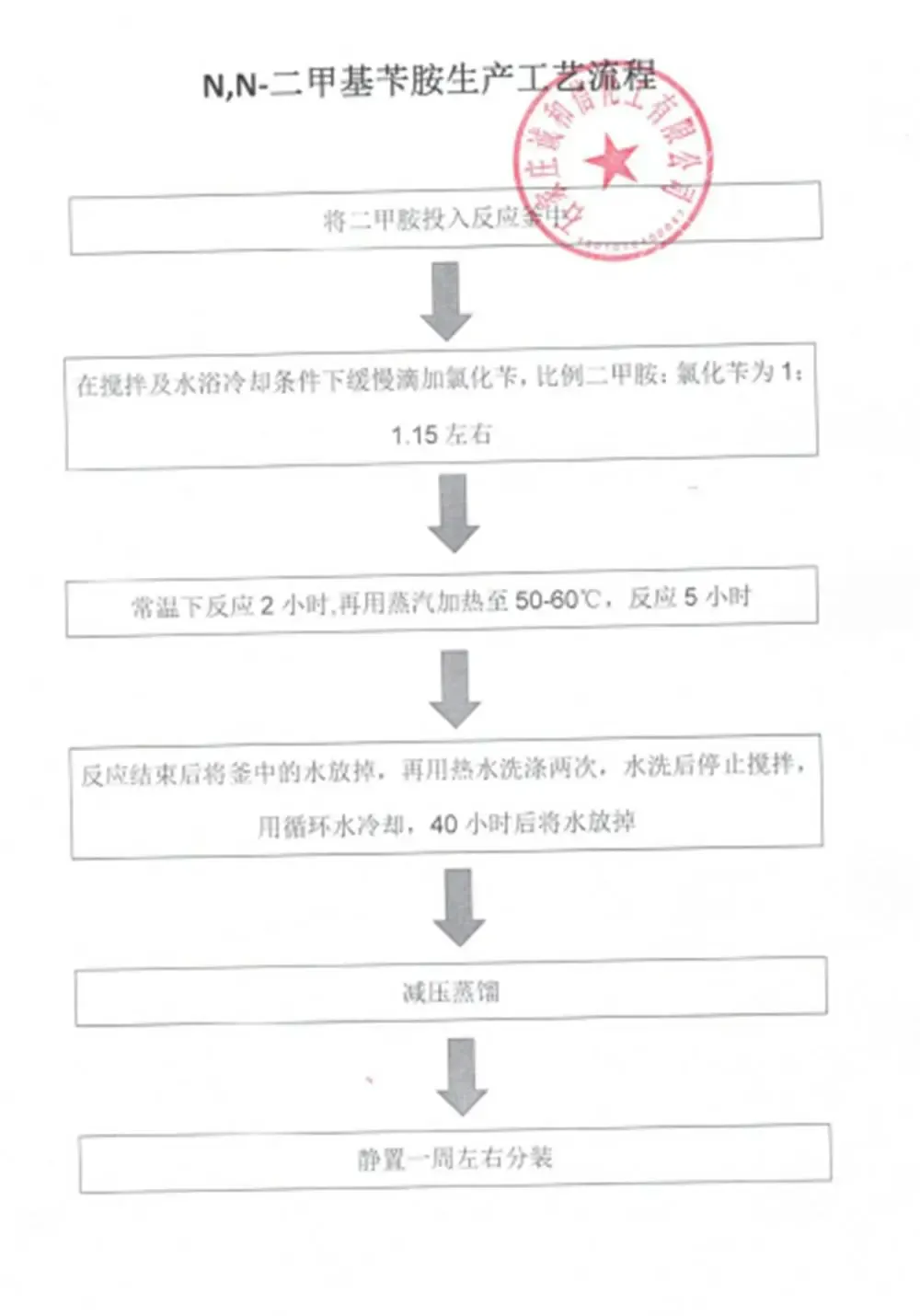

2026-02-09 03:51High Purity N. N-dimethylbenzylamine (BDMA) for Industrial UseExpert Insights | Chemical Technology Analysis N. N-dimethylbenzylamine (BDMA) is an essential terti

2026-02-09 03:51High Purity N. N-dimethylbenzylamine (BDMA) for Industrial UseExpert Insights | Chemical Technology Analysis N. N-dimethylbenzylamine (BDMA) is an essential terti